What Is Magnetic Annealing and how Does it Work?

Annealing is the process of heating a metal piece to increase its ductility and at the same time reduce its hardness, essentially making it more workable. However, during this process, atoms migrate in the crystal lattice, and the number of dislocations decreases, so the piece is undergoing permanent changes as it cools and fully recrystallizes.

In magnets, annealing can end up depriving the metals of their precious magnetic properties, and this is where the process of ‘magnetic annealing’ comes to solve this problem. Besides, with magnetic annealing, one can permanently magnetize a ferrous metal or amplify its magnetic power.

The way it’s done is by applying a relatively strong magnetic field during the thermal annealing process. The idea is that the alignment of the individual atoms on the metal will be forced to homogeneous and symmetrical orientations, so during the cooling process and the subsequent recrystallization, each lattice layer will reach an equilibrium with its neighboring layer and lock into optimal orientation.

Of course, depending on the alloy that is worked, there are different configurations used for magnetic annealing processes. The key thing to always strive for is to generate a large and uniform magnetic field so that the workpiece is treated in a way that produces the desired results. The alignment of the magnetization vectors is also crucially important, and so is the temperature which needs to be uniform across the entire work area.

It goes without saying that this precision goes beyond human guesswork, even for experienced metallurgists, so magnetic annealing can only be carried out using a computerized system. There are modern software-based solutions that can even save “thermal annealing recipes” created specifically for different metals and alloy compositions, while they can also attenuate the intensity and orientation of the magnets based on the given 3D model of the workpiece.

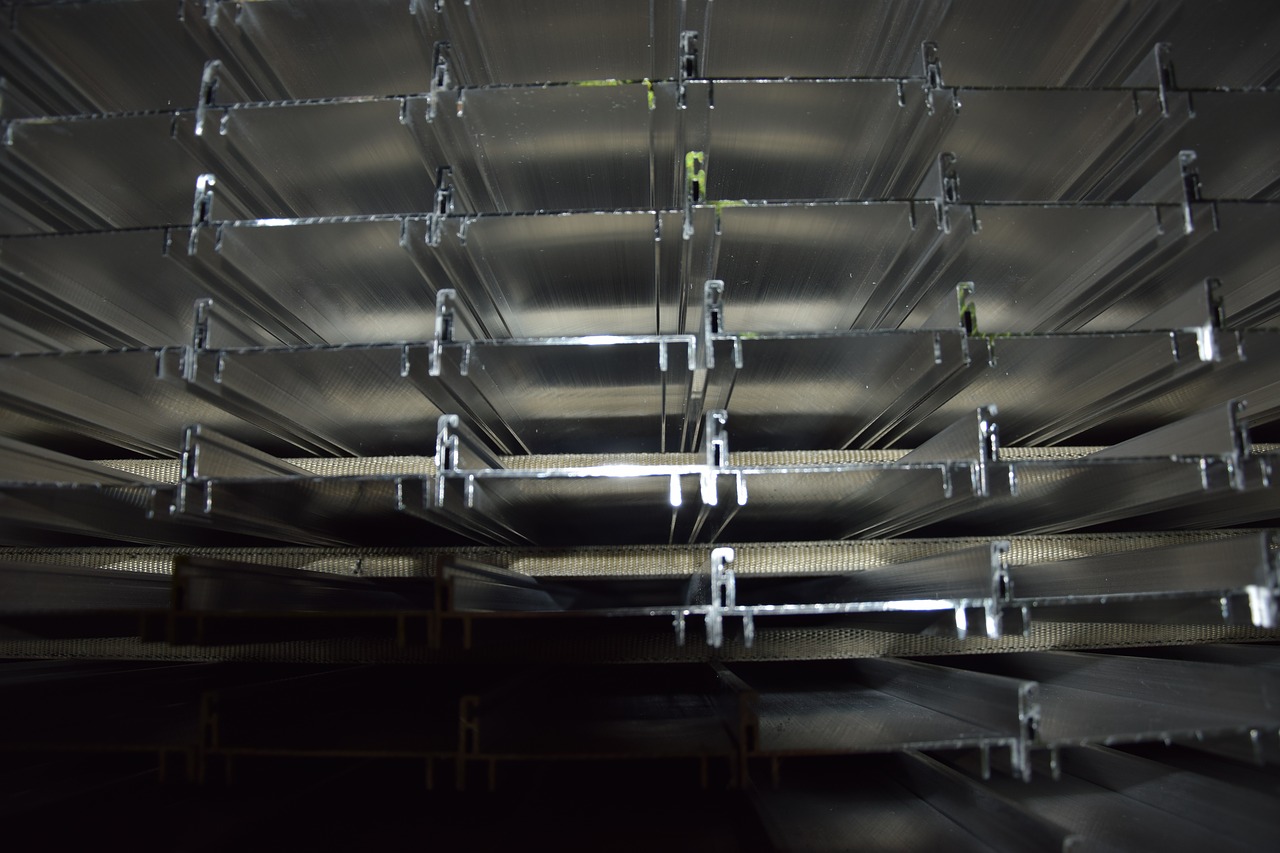

Finally, the furnace has to be insulated so that no heat reaches the external magnets, otherwise their lifetime will be dramatically shortened. These elements are quite pricey, so not paying attention to that little detail is a potentially expensive mistake.

Tech Steel & Materials

Tech Steel & Materials