The World of Welding: Types of Welding Processes

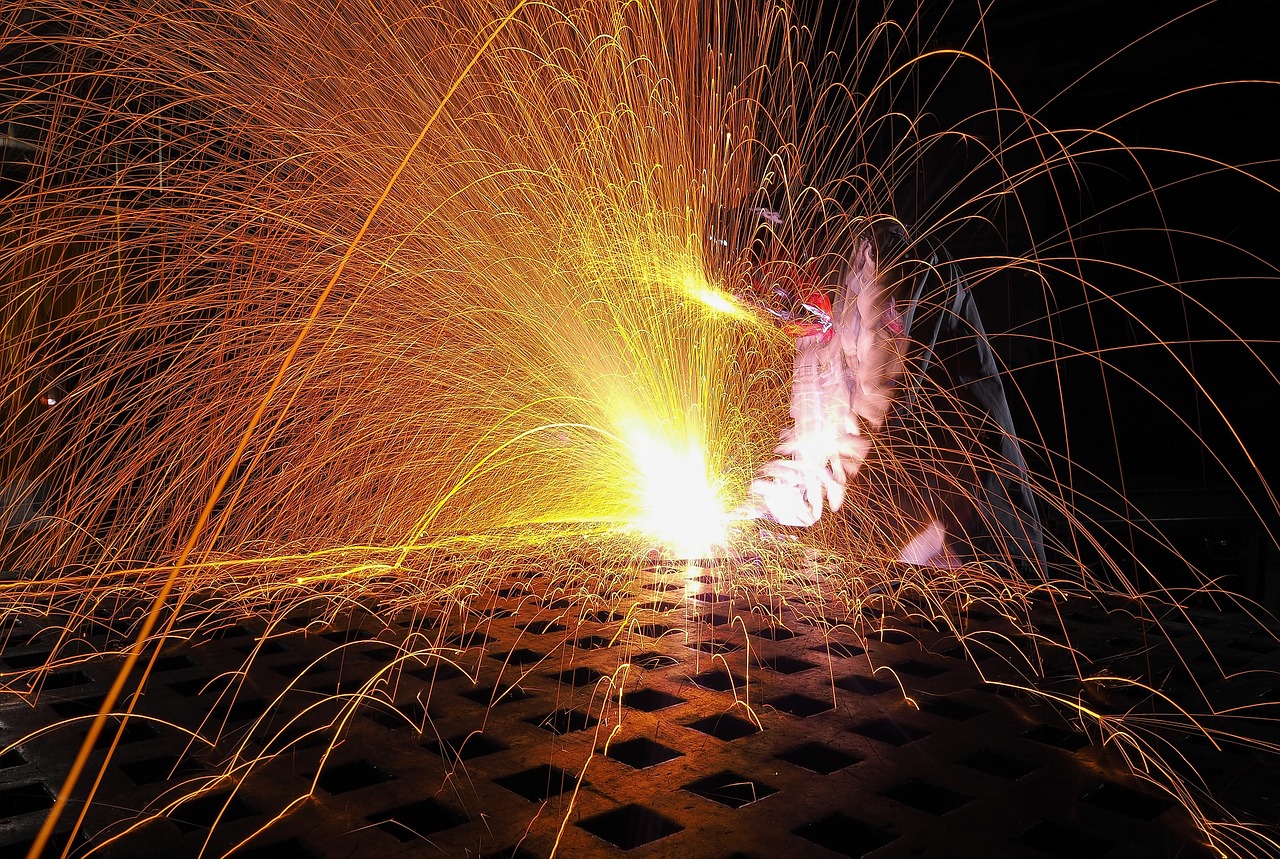

The definition of welding is the process of fusing materials by applying heat and pressure to the materials being combined. Today, many welding processes are automated, but it’s still important to understand the differences between welding techniques in order to pick the right welding technique for the job.

Some main fields of welding are grouped below:

- Boilermakers welders

- Pipefitters welders

- Structural & Pressure Vessel Welders

- Fabrication, Manufacturing, and Production Welder

- Auto body Welder

- Underwater Welding

Different Types of Welding Processes

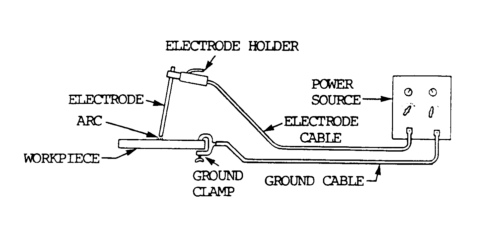

1. Shielded Metal Arc Welding (SMAW/STICK)

This technique follows the process of stick welding. The stick uses an electric current to form an electric arc between the stick and the metals to be joined, melting the joints together. This type of welding is often used with iron and steel in

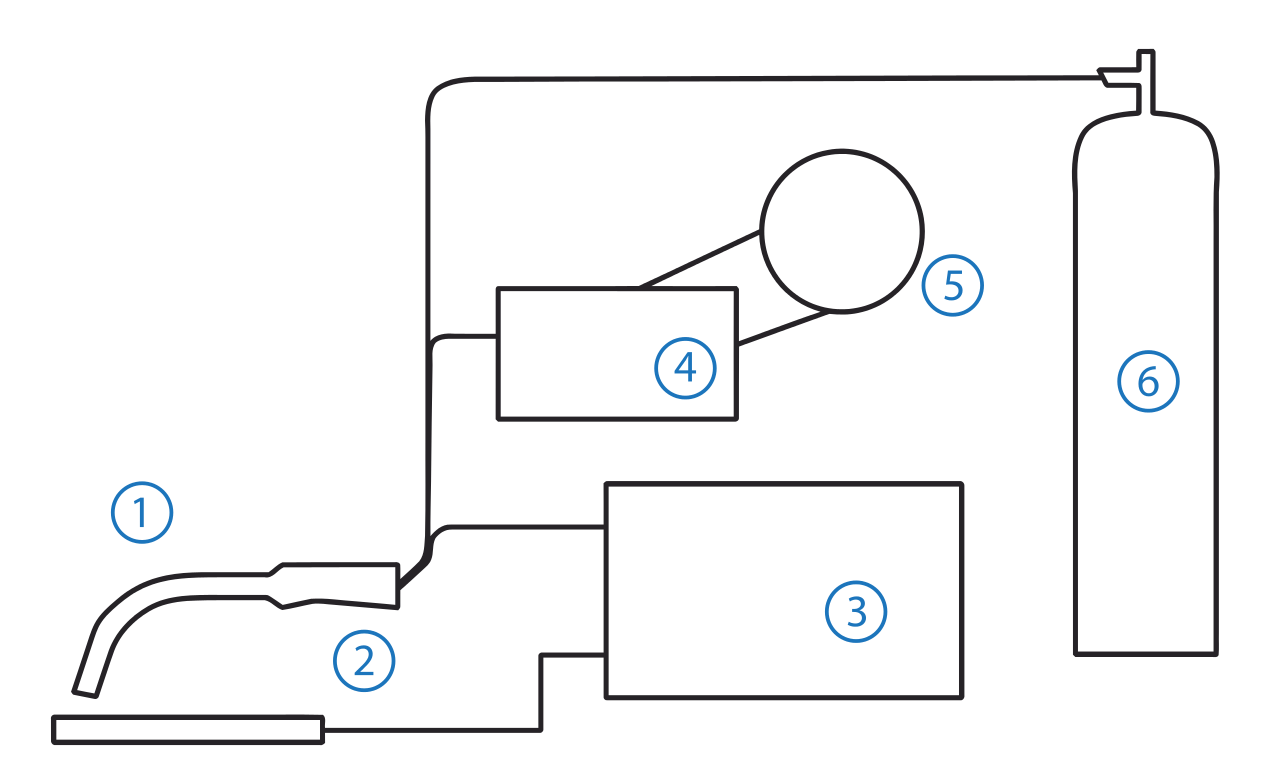

2. Gas Metal Arc Welding (GMAW/MIG)

Credit: Jon C – GMAW_Circuit

This technique uses a shielding gas along the wire electrode. The gas heats up the two metals to be joined using a constant voltage and direct-current power source. Used in common industrial welding, this technique is suitable for fusing mild steel,

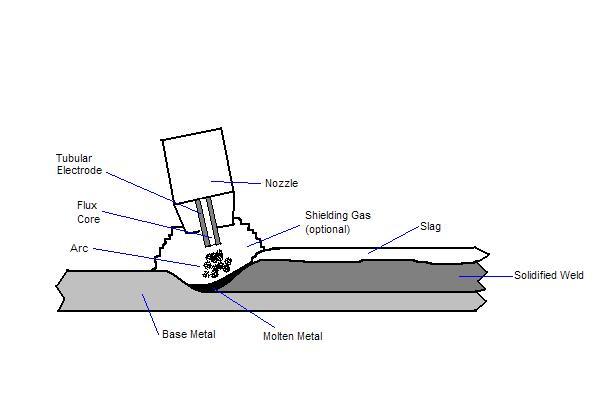

3. Flux Cored Arc Welding (FCAW)

As an alternative to shield welding this technique is very similar to GMAW/MIG welding. However, FCAW differs by using a special tubular wire filled with flux and shielding gas is not always needed. Although not always aesthetically pleasing, it is inexpensive and easy to learn. This technique is largely used in construction projects because of the welding speed and portability.

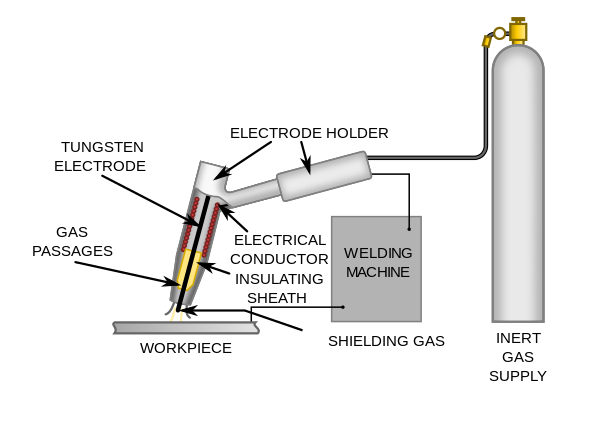

4. Gas Tungsten Arc Gas Welding (GTAW/TIG)

By using a non-consumable tungsten electrode, the base metal is heated to create a molten weld puddle thus melting two pieces of metal together. This technique is used where a high-quality superior standard finish is required without excessive clean up by sanding or grinding. This technique is used to melt thick sections of stainless steel or non-ferrous metals together and is a time-consuming method.

Last thoughts

Working with metal can be intimidating and requires a lot of work and practice. By mastering these techniques, a sense of empowerment is achieved.

Tech Steel & Materials

Tech Steel & Materials