New Laser-Based Welding Promises to Cut Energy Consumption In Construction

Researchers at the Fraunhofer Institute in Germany have developed a novel laser-based system that can be used for precision and energy-efficient welding of construction metals. According to their measurements, the energy requirements of their system are roughly 85% lower than that of conventional welding methods, while the result is also typically of a higher quality due to more precision control.

This is further accentuated when the welding line is long, where human welders may get tired or are forced to change positions often, and the end result is inevitably not totally homogeneous.

Another problem with traditional welding methods is that a large proportion of the spent energy doesn’t go into the welding process itself, but instead, it’s dispersed in the molecular structure of the metal in the components. This causes thermal damage to the material, sometimes even introducing distortions, and also delays the post-welding treatment process.

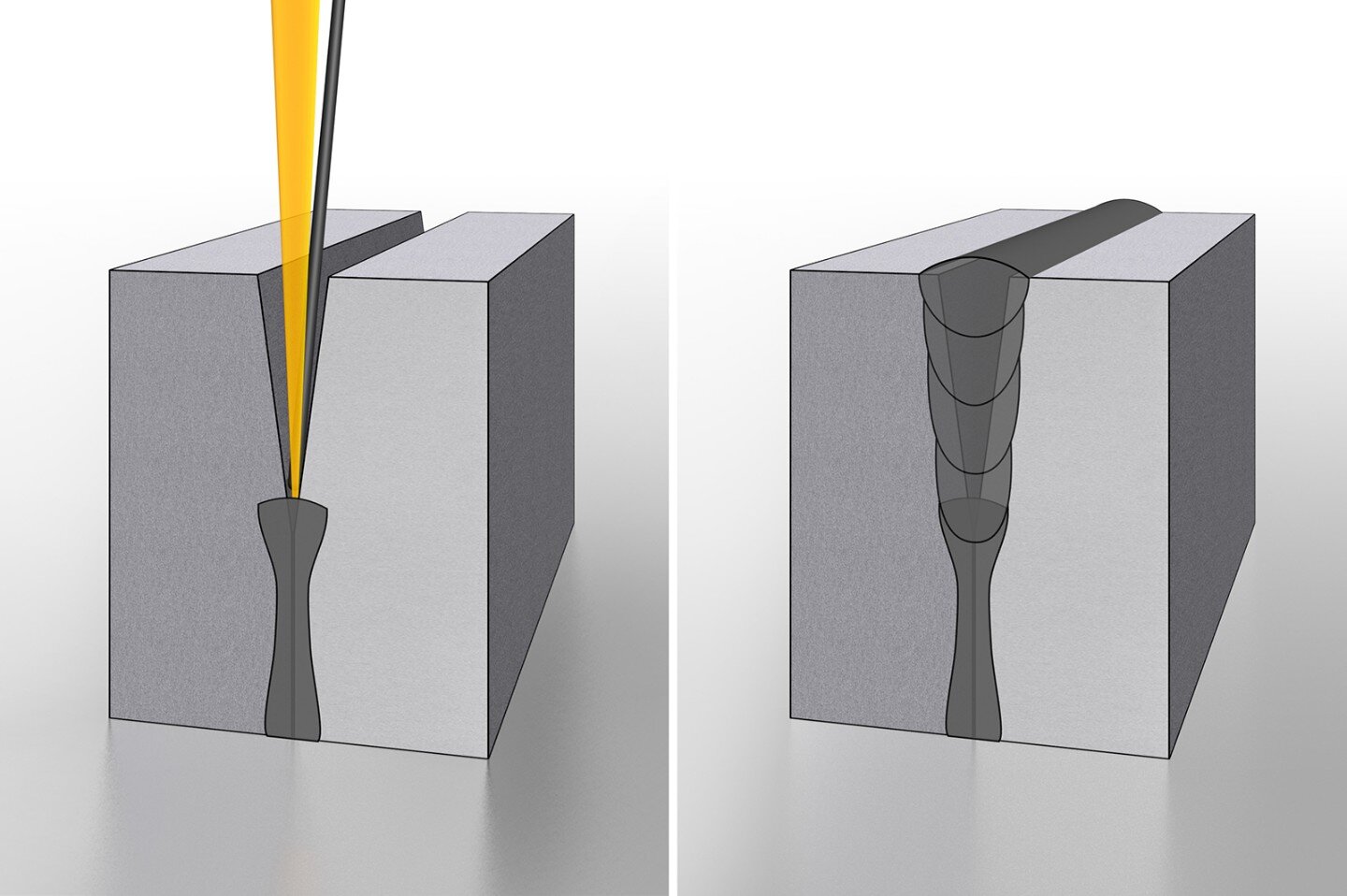

The solution of the Fraunhofer team is to use a high-intensity laser beam that hits the welding line with accuracy and directs heating energy right on the welding point. This reduces the time by up to 70%, energy consumption by 85%, and keeps the component relatively cold.

The team put this system to the test and used an indoor crane segment made of structural steel to demonstrate their laser-based welder. The piece had a length of four meters, and the welds followed the industry-typical standards of a butt joint on 30 mm plates and a complete T-joint on a 15 mm plate.

Compared to submerged arc welding and the required subsequent straightening process that comes with it, the laser-based solution reduced the cost of making a 30 mm thick weld by 50%. For thinner thickness, at 20 mm, the theoretical cost savings reached 80%. Taking that to a grander operational scale would translate to cost cuts of hundreds of thousands of USD.

Tech Steel & Materials

Tech Steel & Materials