How to Calculate Metal Weight

Calculating the weight of a given alloy is a crucial aspect of engineering and manufacturing processes. The weight of a metal component not only influences its performance but also impacts design considerations, material selection, and cost estimation. Here’s a detailed guide on how to accurately calculate metal weight:

Importance of Metal Weight Calculation

The weight of a single piece of alloy with identical dimensions can vary significantly due to variations in material composition. Alloys consist of different elements, each with its own density, making precise weight calculations essential for engineering applications.

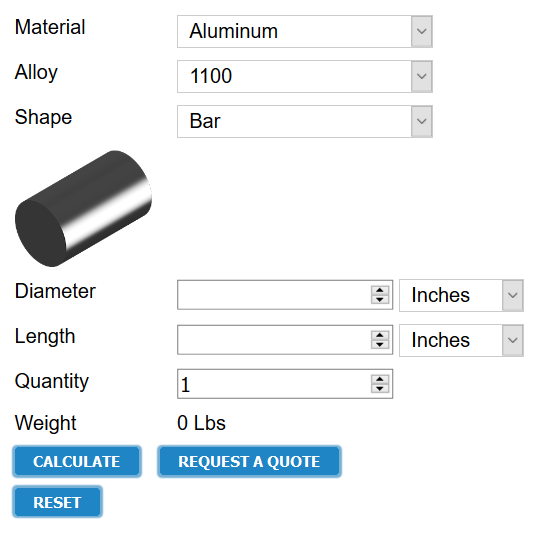

Introducing the Metal Weight Calculator

To simplify the process of determining metal weight, Tech Steel & Materials offers an online Metal Weight Calculator. This tool allows engineers and designers to quickly and accurately estimate the weight of various metal parts, including sheets, plates, tubes, bars, and more. It supports a wide range of alloys, including Aluminum, Cobalt, Magnesium, Nickel, Stainless Steel, Titanium, and Tool Steel.

With our calculator, you can easily find how much a said part weighs. The calculator works with every alloy from our repository, including Aluminum, Cobalt, Magnesium, Nickel, Nickel Copper, Stainless Steel, Steel, Titanium, and Tool Steel alloys.

Moreover, our Metal Weight Calculator can calculate the weight of many different parts and shapes, including sheet, plate, strip, tube, bar, rod, wire, extrusion, ring, forging. The only thing you need to do is to enter the dimensions of the part (diameter, length, and quantity), and you will quickly get the entire metal weight.

Our Metal Weight Calculator can certainly simplify the process of calculating the weight. However, the number you get at the end will be an estimation, which is why we recommend additional computations to be made for practical use.

Calculating Metal Weight Manually

To calculate the weight of any part, you need to first calculate the volume of the shape. Then, you should use the density of the alloy. You can find the density of any alloy in the “Mechanical and Physical Properties” table on the web page of each alloy available through Tech Steel & Materials.

Please note that we provide both imperial and metric measurements for any alloy. You should always calculate using the imperial lb/in3 with inches, and the metric g/cm3 with centimeters. Never use imperial with metric measurements during calculations!

Calculating the Volume of the Metal Part

You can calculate the volume of any part using a simple formula. For rectangular pieces, you will need these dimensions:

- The length of the part

- The width of the part (or diameter)

- The thickness of the part (or diameter)

You can get the full volume of the part by multiplying all values in case of a square bar, plate, or sheet: Volume = Length x Width x Thickness

For Round Bar Volume, use the next formula:

Volume = π × (Diameter ÷ 2) × (Diameter ÷ 2) × Length

For Square Tube Volume, use the next formula:

Volume = (Width – Wall thickness) × Wall Thickness × 4 × Length

For Round Tube Volume, use the next formula:

Volume = (Outer Diameter – Wall thickness) × Wall Thickness × π × Length

After you found the volume of the part, just multiply it with the density of the alloy, respecting the imperial and metric measures:

Metal Weight = Volume x Density

In practice:

Let’s take a Stainless Steel 422 square plate with 10x4x2 inches (10″Length x 4″Width x 2″Thickness) as an example:

Volume = 10 x 4 x 2 = 80 in3

Then, we are multiplying the volume with the density of Stainless Steel 422, which is 0.28 lb/in3:

Metal Weight = 80 x 0.28 = 22.4 lb

DISCLAIMER: The weights shown using this metal weight calculator should be used for estimation purposes only. They are calculated using nominal dimensions and scientifically recognized densities. Please note that in practice, the actual metal weight can vary due to variations in manufacturing tolerances and compositions. Tech Steel & Materials makes no warranty based on the results from this metal calculator, and we will not be responsible or liable for any errors and damages that may arise based on the calculated results.

Tech Steel & Materials

Tech Steel & Materials