Fire Safety Assessment Test on Stainless-Steel Containers Leaves Engineers Puzzled

Engineers at Sandia National Laboratories have carried out a series of tests on specially designed stainless-steel containers used by the U.S. Department of Energy for storing and transporting hazardous materials, and the results of the tests are confusingly inconclusive.

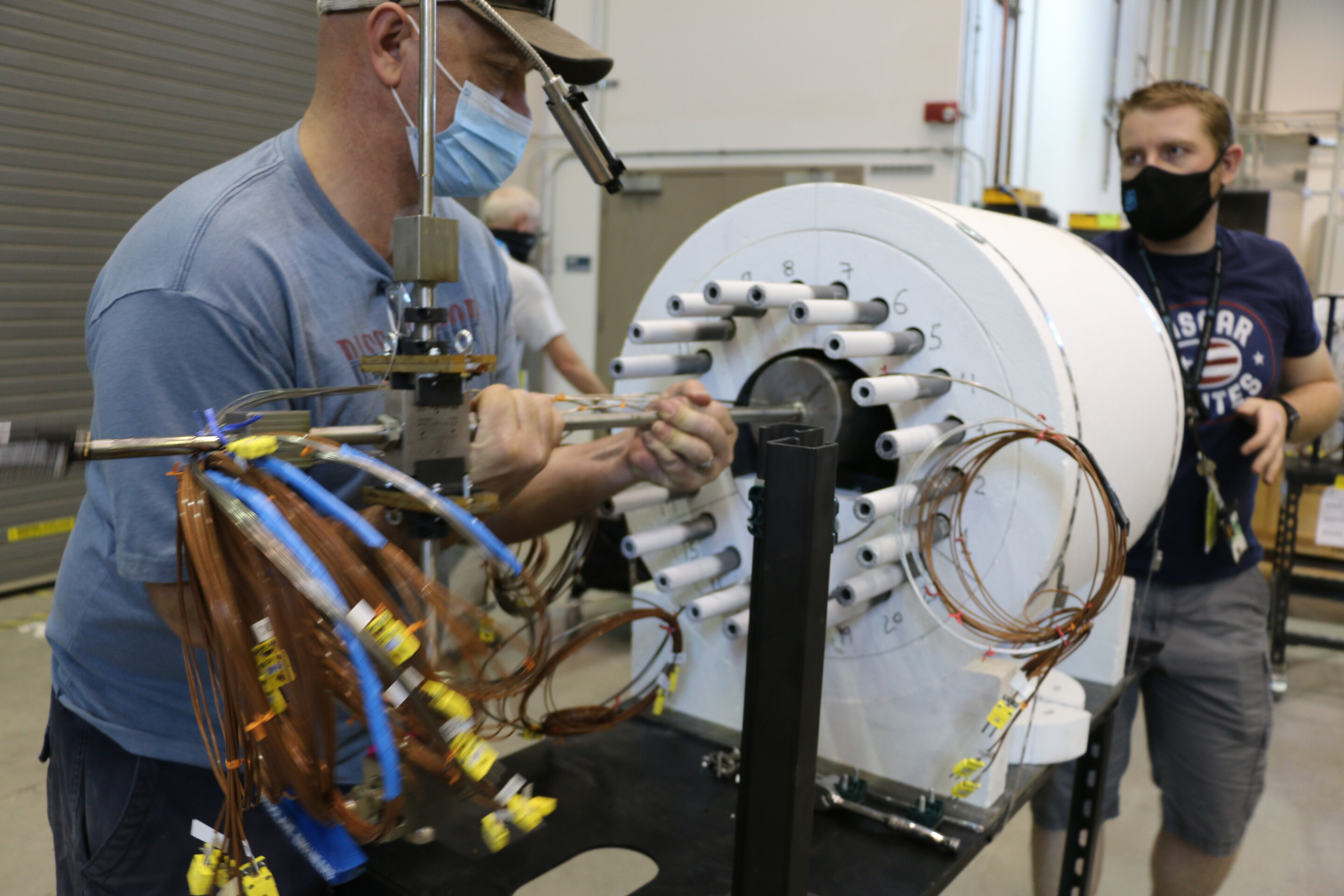

The goal was to test what happens in the case of a fire and to see how much of the dangerous materials inside the contains would leak out. Each container was outfitted with 18 temperature sensors, two pressure sensors, a camera to give live feed from the inside, and was also X-rayed during the fire tests.

The process involved heating the containers up to 2000 degrees Fahrenheit (1093 OC) for four hours, mimicking the scenario of a very unfortunate accident in a remote location away from the reach of firefighters.

The melting point of stainless steel is higher, at 2750 OF, but its useful service limit is considered to be 1700 OF, as beyond this point it loses much of its strength. As such, the containers weren’t designed to sustain that temperature for that long.

What happened is that none of them split open or leaked any material, which was not the outcome the engineers who designed and conducted the experiments expected to see.

One explanation of what may have happened is this: The containers are layered, so the internal shell may have reacted with the mixture inside and formed pinholes that allowed the release of pressure without creating obvious ruptures.

Another theory is that the super-heated steam seeped through the steel walls of the container, and created a pressure equilibrium. This again prevented the creation of cracks on the container’s layers.

To figure out what happened, the scientists are analyzing the produced gasses that could reveal any chemical reactions that might have taken place during the four hours of the simulated fire.

Stainless steel as a material has once again proved why it’s so ubiquitous and versatile, even being able to withstand tests that were designed to push it beyond its physical limits.

Tech Steel & Materials

Tech Steel & Materials