Engineers Try Out Material Combinations to Create Stretchy Electronics

Image: Felice Frankel

Engineers have been trying to develop durable flexible electronics for quite some time now, envisioning numerous applications concerning wearables and “smart clothing”. The team that is close to cutting the ribbon first is a group of researchers from the MIT and University of Wisconsin, in the United States.

The same team of engineers has been working on this project since 2017, and they have previously presented a couple of exciting tentative approaches, so this isn’t coming as a surprise.

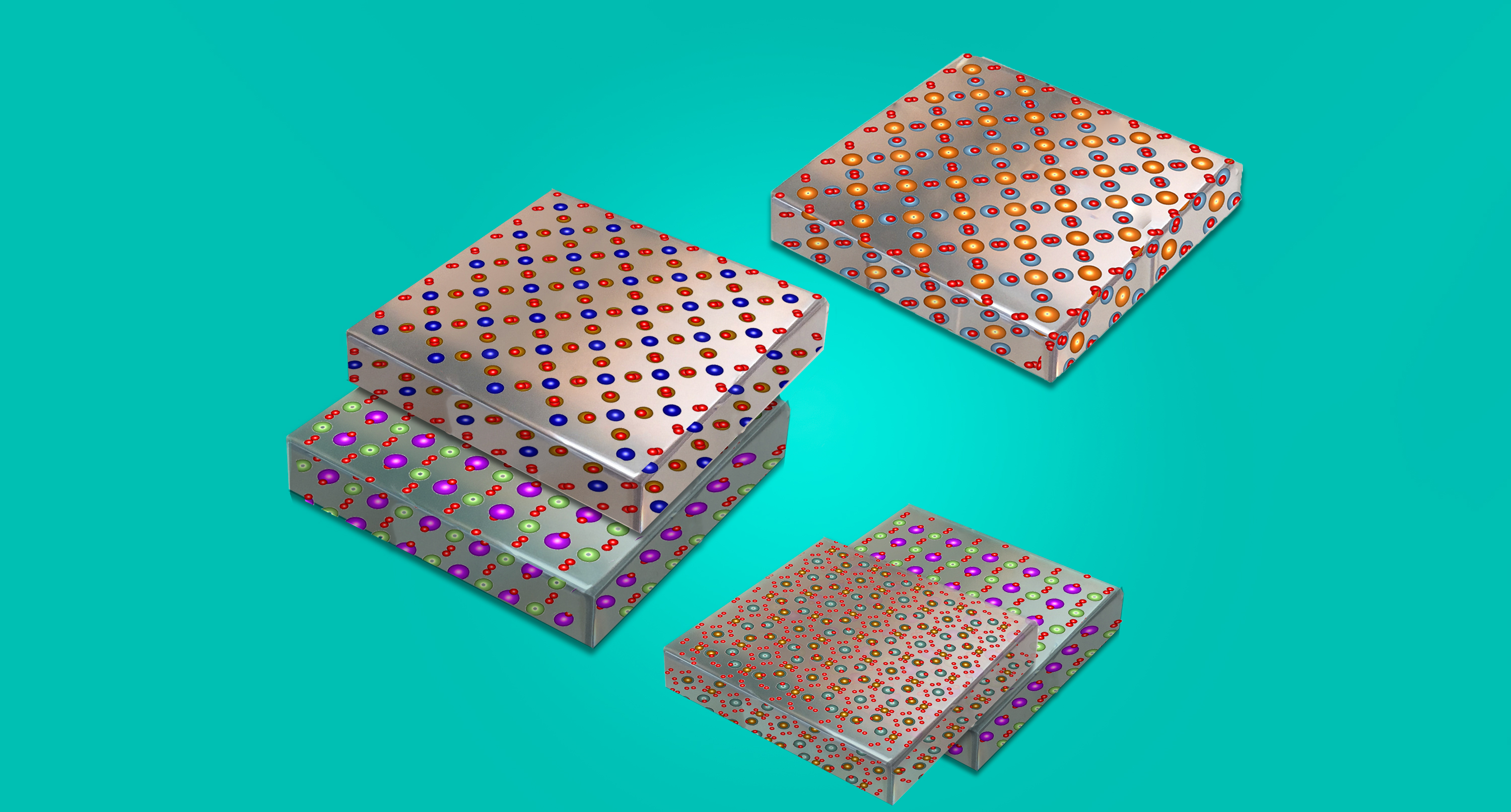

The most recent creation demonstrates a “peel and stack” approach that the engineers use to create films of oxide materials. The peel concerns the controlled removal of a very thin (100 nm) layer, and the stacking of layers of different materials (cobalt, ferrite) to create a single electronic unit. The team feels like they’re building with “LEGO” blocks, as they place wafer upon wafer to end up with a functional device.

The great thing about this method is that the engineers don’t have to consider the crystalline pattern differences between the various materials, so the limitations of the traditional epitaxy techniques don’t apply on the “peel and stack”. As the team’s leader puts it, whatever you can imagine, you can realize it through this method. Already, they have made sensors, solar cells, small batteries, and computing chips.

Different combinations of materials are ideal for different electronic units, so there’s a lot of experimentation left to be done yet.

Thankfully for the team, DARPA (Defense Advanced Research ProjectsAgency) is supporting their effort, as the U.S. Army would be very interested in deploying flexible chips in military uniforms.

Flexible chips could be used to measure and communicate the soldier’s biometric data, geographic location, status, and more, and DARPA has been actively trying to deliver something tangible in this sector for years now.

Tech Steel & Materials

Tech Steel & Materials