Condenser Coating for Power Plants Holds Potential to Reduce CO2 Emissions by 460 Million Tons Annually

Gradually phasing out global dependence on fossil fuels is an ongoing process. Therefore, it’s essential to explore methods that can enhance the efficiency of energy production.

In this endeavor, researchers at the University of Illinois Urbana-Champaign have introduced a pioneering coating for steam condenser pipes. With widespread adoption, this advancement could lead to an energy surplus comparable to Russia’s annual output.

A Sustainable Solution with Far-reaching Impact

Numerous power generation techniques operate on the principles of the steam cycle. This involves utilizing energy sources such as fossil fuels or nuclear fission to heat water within a boiler. The resulting steam drives turbines, thus generating electricity. The condensed steam is collected in a condenser, where water is recovered to sustain the cycle.

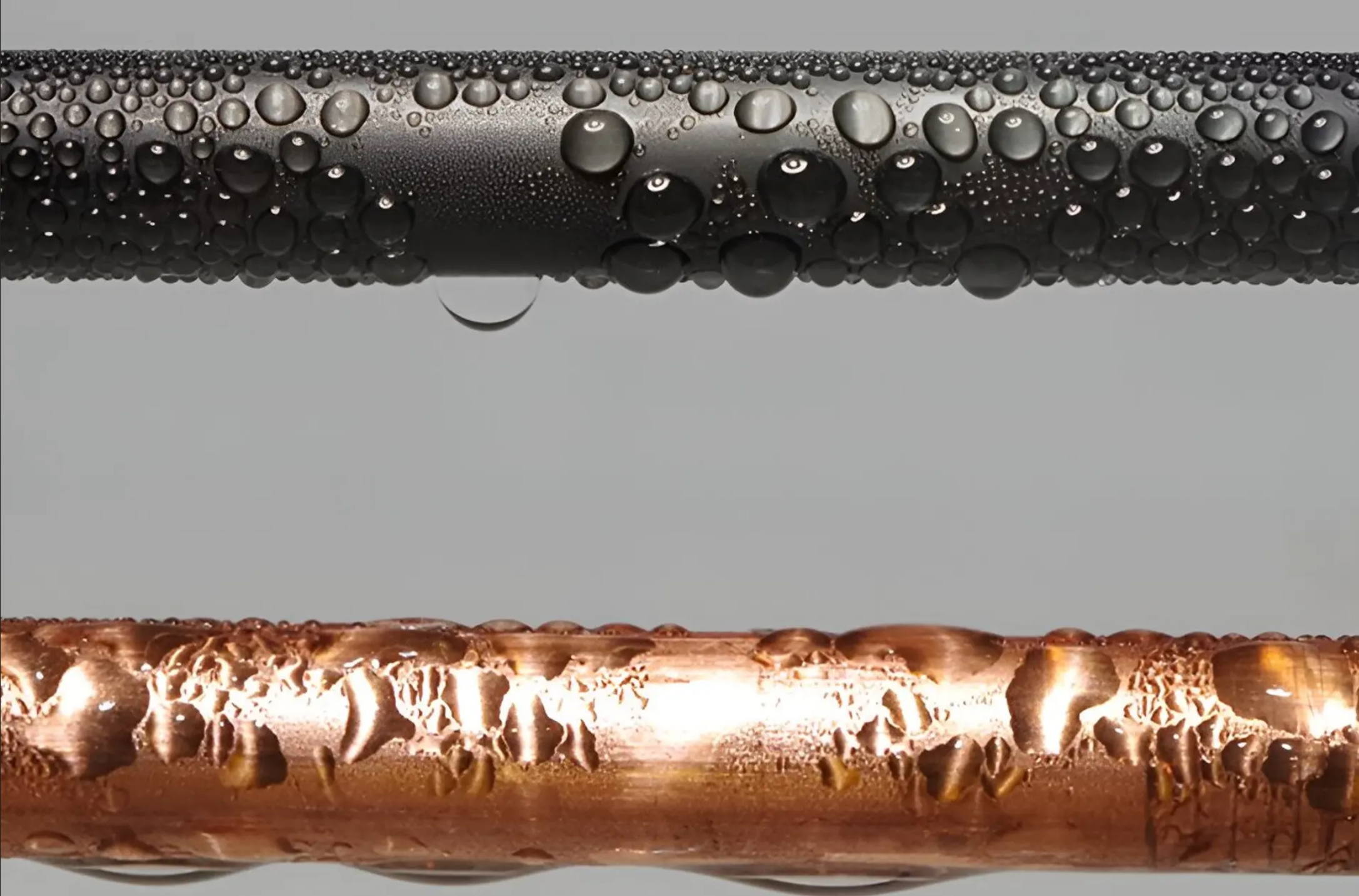

The driving force behind a recent study was to enhance heat transfer efficiency within condenser pipes. The researchers accomplished this goal by developing a coating using a hydrophobic material called fluorinated diamond-like carbon (F-DLC).

With this coating, condensed steam forms droplets instead of a thin film, allowing for faster drainage. This innovative approach ensures increased direct contact between steam and pipe surfaces, thereby optimizing heat transfer.

Experiments Yield Remarkable Results:

In experimental trials, the team observed an astonishing 20-fold improvement in heat transfer due to the newly developed coating. This advancement translated into an overall efficiency increase of 2%.

If scaled up, this progress could potentially elevate global annual electricity generation by a substantial 1000 TWh. Notably, this is equivalent to approximately 83% of the electricity output from worldwide photovoltaic installations, all achieved without contributing additional carbon emissions.

“It’s remarkable that we can achieve this with F-DLC, something that just uses carbon, fluorine, and a little bit of silicon,” said Muhammad Hoque, lead author of the study. “And it can coat pretty much any common metal, including copper, bronze, aluminum, and titanium.”

Future Prospects and Economical Viability

Nenad Miljkovic, the project’s lead researcher, expressed optimism about the coating’s potential impact. While renewable energy development remains crucial, Miljkovic underlined the value of improving current energy generation methods. The researchers are eager to showcase the effectiveness and economic viability of their solution, aiming for broad adoption.

The results of this groundbreaking study have been documented in the journal Nature Communications.

Article Source: Industry Tap

Tech Steel & Materials

Tech Steel & Materials

Comments are closed