What Is The Difference Between Steel Billets and Steel Bars?

Steel is perhaps the most versatile material used to build everything around us, from buildings and bridges to cars and aircraft. Depending on the application and manufacturing process, steel comes in various forms. Two of the fundamental forms are billets and bars, which are refined and ready-to-use forms of steel tailored for production purposes.

At Tech Steel and Materials, we are serious about the products we produce from start to finish. Steel billets and bars are one of our specialties – but what is the difference between them? Let’s have a closer look because billets and bars possess different characteristics and thus are used for different production methods.

What are Steel Billets?

Steel billets are the product of melting iron ore or scrap iron using a method first introduced in the 19th century known as the Bessemer process.

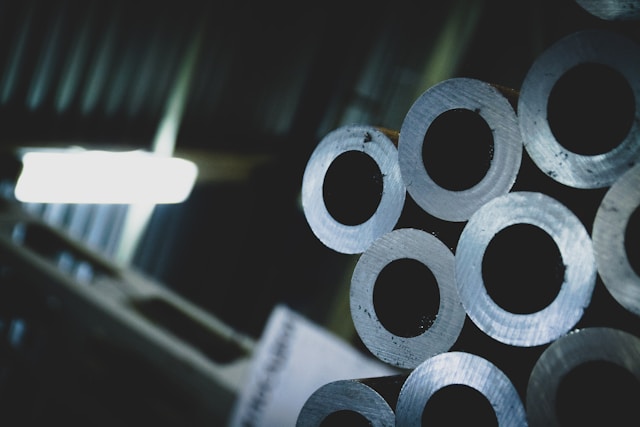

Billets are also known as the second-stage product of steel production. They can be produced in two ways, namely continuous casting or rolled directly from the casting process by billet mills. Steel billets are very ductile and are produced in square cross-sections, ranging in width and length from a few inches to several feet. As such, they are very versatile in production.

However, they are not always practical until they have been formed into various shapes and sizes to be sold at hardware stores or used for other applications. Usually, billets are made from carbon or alloy steel and are considered a semi-finished product.

What are Steel Bars?

Steel bars are also known as long products of steel billets, usually round, square, rectangular, or have a hexagonal cross-section. They are produced using several processes, like hot rolling, cold rolling, and forging.

The composition and mechanical properties of steel bars vary depending on their intended use, with specific types like reinforcing bars (rebars) being common in concrete reinforcement.

Notably, a billet gets folded/rolled to form a much stronger reinforcing bar (rebar) produced by tight-rolling of steel billets in walking-beam furnaces with temperatures up to 1 200°C (2 192°F).

The most prominent use of bars can be found in the construction of buildings; however, according to their shapes and size, they can also be used in Military weapons, building vehicles, etc.

How are Steel Billets Made?

The manufacturing of steel billets starts with the melting of raw materials in a high-temperature furnace, which usually includes scrap steel or direct reduced iron. The specific content can vary depending on the type of steel.

Once molten, the steel is purified, which is crucial to give it good mechanical and chemical properties, and then it is cast into semi-finished, rectangular billets in a continuous casting process for maximum efficiency. As a result, steel billets are relatively cheap to make, particularly when compared to other forms.

The steel billets are then cut to desired lengths by the manufacturer. In some cases, the manufacturer could use additional rolling or shaping if necessary.

How are Steel Bars Made?

The manufacturing of steel bars actually starts with a steel billet, which undergoes a series of rolling processes depending on the desired quality and properties.

Hot rolling, which is the most common manufacturing process, includes heating the billets at high temperatures for easier formability and then passing them through a series of rollers to achieve the desired shape and size of the steel bar.

In some steel bars, hot rolling is followed by cold rolling, where the steel is rolled at room temperature to achieve higher strength, tighter tolerances, and smoother finishes.

Manufacturers can also use various heat treatments to improve the physical and mechanical properties of the steel bars, particularly strength and ductility.

Common Uses of Billets and Bars

Steel billets are considered crucial in the steel production chain and are used for a wide range of steel products. In industrial settings, they are commonly used for the production of bars, rods, and wires, which are foundational elements in construction and manufacturing.

Thanks to their malleability and versatility, steel billets are used for manufacturing large structural sections in construction and architecture. Other uses of unformed billets include striking currency such as coins and are also used as reserves like gold bars.

Steel bars are a more finished form of steel compared to billets, though by no means is their applicability any smaller. Notably, reinforcing steel bars (rebars) are essential in building the backbone of our society, as they are used to reinforce concrete by enhancing its tensile strength.

Other industries also use steel bars to produce bolts, nuts, engine parts, and machinery components. Basically, any industry sector that requires parts with good ductility, strength, and versatility.

Price and Availability

Steel billets are considered fundamental raw materials globally and are thus readily available in every market. The cost of billets largely depends on the global demand-supply dynamics, geopolitical factors, and simply the price of raw materials, which vary depending on the type of steel.

That said, billets are cheaper than bars because they are almost always traded in higher quantities and to large companies. Moreover, the production process is generally less demanding.

Meanwhile, apart from the factors that affect steel billets, the price of steel bars is also impacted by the production process. Notably, the desired type of bar (e.g., rebar, flat bar, round bar), size, and grade can significantly impact the cost.

Steel bars are generally available through a network of suppliers and distributors, making them easily accessible to both large-scale projects and individual consumers.

At Tech Steel & Materials, we supply the specialty metals in today’s high-performance applications demand. Count on us to meet your toughest challenges, tightest time frames, and most exacting performance specifications!

Tech Steel & Materials

Tech Steel & Materials