3D Printing With Titanium And Stainless Steel

With the world set to build skyscrapers twice as tall as current structures and plans for near and far space exploration, analysis shows new materials with the requisite characteristics need to be discovered or invented. For new skyscrapers concrete and steel will no longer do and materials making up heavy lift rockets need greater strength and durability. NASA’s SLS or Space Launch System, being developed at the Marshall Center, will travel beyond low Earth orbit to nearby asteroids and eventually to Mars, ferrying humans, equipment and experiments.

“Additive Manufacturing” Laser Melting Methods Are The Future

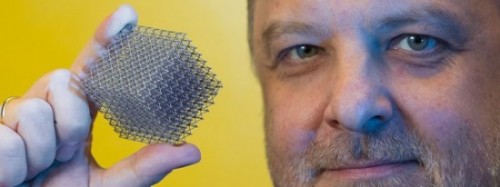

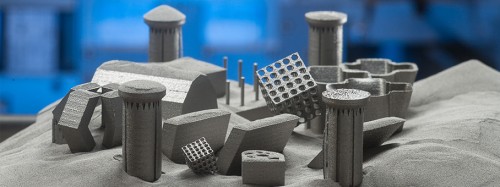

There are two different laser melting methods: “laser beam melting” using a powder bed and “laser build-up welding,” also known as “laser cladding” or “laser consolidation.” These are part of what is known as “additive manufacturing” and they will change manufacturing radically. These two methods allow parts to achieve a density of almost 100% so conventional metals such as titanium, stainless steel and cobalt chrome can be used, and the process makes them stronger than previously. These techniques have been around since the 1980’s, but they are just beginning be considered for widespread use in manufacturing.

SLS, for example, is a method for creating intricate metal parts out of metal powder by bombarding them with a shower of sparks. The parts are made in a mold bed where a hexagonal laser moves across the surface of powder converting it into a solid material; the process can be viewed behind an observation window. The laser beam is, of course, computer-controlled and follows an electronic blueprint melting new parts from stainless steel powder. The laser raises the temperature of the powder to the melting point, about 1,500°C. The stainless steel workpiece is built up in 50-micrometer thick layers.

The process gives the fine particles a characteristic structure and surface significantly stronger than current processes and the need for warehousing spare parts is eliminated; computers and 3D printers can quickly print from digital designs whether the printer is nearby or thousands of miles away.

Via: www.industrytap.com

Tech Steel & Materials

Tech Steel & Materials