Aluminum 6061

View AMS Numbers >

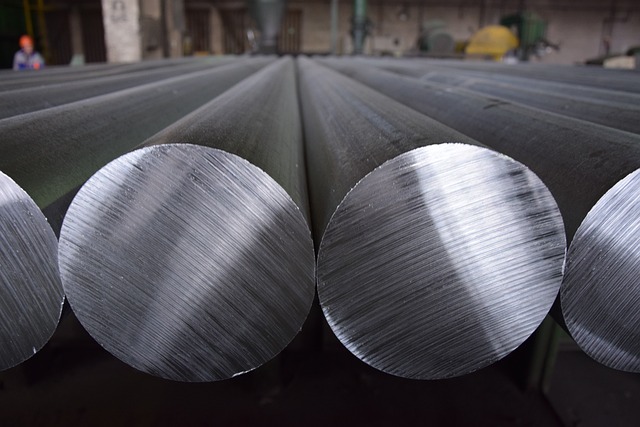

Aluminum 6061

6061 aluminum is among the most widely used heat-treatable alloys. A critical material in many demanding applications, it provides a balance of strength, machinability, weldability, and excellent corrosion resistance. Plus, it’s heat treatable. 6061 aluminum has a high-strength-to-weight ratio and is stronger than pure aluminum but significantly lighter than steel and copper. This material is ideal where strength and lightness are factors.

Tech Steel & Materials offers Aluminum 6061 in 16 sub-type specifications, each in multiple and customized shapes/forms.

Key Features of 6061 Aluminum

- Strength-to-Weight Ratio: With a high-strength-to-weight ratio, 6061 aluminum surpasses pure aluminum in strength while maintaining a significantly lighter weight compared to steel and copper.

- Thermal and Electrical Conductivity: Boasting excellent thermal conductivity, 6061 aluminum finds its niche in heat sinks and other applications requiring efficient heat transfer. Additionally, its commendable electrical conductivity makes it an ideal choice for various electrical devices.

- Corrosion Resistance: Resisting corrosion from concentrated nitric acid, ammonia, and ammonium hydroxide, 6061 aluminum ensures longevity and reliability even in harsh environments.

The Composition of 6061 Aluminum:

| Element | Limiting Chemical Composition (%) |

| Aluminum | 97.9% |

| Magnesium | 1.0% |

| Silicon | 0.6% |

| Copper: | 0.28% |

| Chromium | 0.2% |

| Aluminum | 0.20%-0.80% |

| Other Elements | 0.15% |

Fabrication and Working Instructions

6061 aluminum facilitates easy fabrication and machining. Sharp cutting tools coupled with appropriate lubrication ensure clean, precise cuts and reduce the risk of burrs. It’s crucial to avoid overheating during work, as excessive heat softens the material, impeding workability.

6061 aluminum is among the most recycled materials in the world, capable of being recycled repeatedly without losing any of its quality.

Weldability and Finishing

This alloy presents excellent weldability using various methods such as TIG, MIG, and arc welding. Choosing a compatible filler metal, such as 5356, ensures optimal welding results. Furthermore, 6061 aluminum lends itself well to diverse finishing techniques, including anodizing, painting, and powder coating, catering to specific aesthetic and performance requirements.

Properties of 6061 Aluminum

The mechanical properties of 6061 aluminum T6 are as follows:

| Mechanical Properties (T6 Temper) | Imperial | Metric |

| Ultimate Tensile Strength | 45,000 psi | 310 MPa |

| Tensile Yield Strength | 40,000 psi | 276 MPa |

| Elongation Break | 12% | 12% |

| Young Modulus | 10,000 Ksi | 69 GPa |

The physical properties of 6061 aluminum are as follows

| Density | 2.7 g/cm^3 |

| Melting Point | 585 °C (1,085 °F) |

| Thermal Conductivity | 152 W/(m·K) |

| Linear Thermal Expansion Coefficient | 2.32×10−5 K−1 |

| Specific Heat Capacity | 897 J/(kg·K) |

| Hardness (Rockwell B) | 60 |

| Hardness (Vickers) | 107 |

Heat Treating 6061 Aluminum

Heat treating 6061 aluminum is necessary to achieve the desired properties. The part must be clean and free from grease and oil. Use a calibrated furnace to ensure the aluminum is heated to the correct temperature.

The solution heat treatment temperature for 6061 aluminum is 985 degrees F. (530 degrees C.). It’s also essential to heat the material evenly to avoid distortion, which can be done by rotating the part in the furnace or by using multiple burners.

Hold the part at the solution heat treatment temperature for the correct amount of time. That varies depending on the thickness of the part but is typically around one hour per inch of thickness.

Quenching the part rapidly in water after heat treatment locks in the dissolved alloying elements and prevents them from reprecipitating. Quenching also prevents the formation of large precipitates that can weaken the part.

Avoid distortion when quenching the part in water by supporting it in a fixture or using a tank large enough to accommodate the part without crowding.

Age the part after quenching it. The most common aging temperature for 6061 aluminum is 350 degrees F. (177 degrees C). The most common aging time is 8 hours.

Let the part cool to room temperature after aging. If you’re unsure about any aspect of the heat treatment process, consult a qualified heat treater.

Applications & Common Use of 6061 Aluminum

- Aerospace: Aircraft wings and fuselages, helicopter rotor blades, landing gear, engine parts, fuselage frames

- Automotive: Engine blocks/heads, transmission cases, brake calipers, suspension components, Wheels, and rims

- Construction: Building facades, roofing, structural beams and columns, bridges, towers and pylons

- Marine: Ship hulls and superstructures, boat frames and decks, docks and piers, fishing boats and yachts

- Electronics: Heat sinks, heat exchangers, enclosures, circuit boards, battery cases

- Furniture: Chair frames, table frames, bed frames, desk frames, outdoor furniture

- Fasteners: Rivets, screws, washers, and nuts and bolts

Additional applications include bicycle frames, motorcycle frames, scuba tanks, camera lenses, fishing reels, archery equipment, medical devices, and sporting goods

For precision-engineered components and unparalleled performance, trust in the reliability of 6061 aluminum.

Select AMS Number:

| AMS Number | Alloy | Type | UNS | Cross Ref. Spec | Misc./Shape | |

|---|---|---|---|---|---|---|

| AMS 4021 Plate | 6061 | Aluminum | A86061 | - | Plate |

|

| AMS 4021 Sheet | 6061 | Aluminum | A86061 | - | Sheet |

|

| AMS 4022 Plate | 6061 | Aluminum | A86061 | - | Plate |

|

| AMS 4022 Sheet | 6061 | Aluminum | A86061 | - | Sheet |

|

| AMS 4023 Plate | 6061 | Aluminum | A96061 | - | Plate |

|

| AMS 4023 Sheet | 6061 | Aluminum | A96061 | - | Sheet |

|

| AMS 4025 Plate | 6061 | Aluminum | A96061 | - | Plate |

|

| AMS 4025 Sheet | 6061 | Aluminum | A96061 | - | Sheet |

|

| AMS 4079 Round | 6061 | Aluminum | A96061 | WW-T-700/6 | Round |

|

| AMS 4079 Tubing | 6061 | Aluminum | A96061 | WW-T-700/6 | Tubing |

|

| AMS 4080 |

6061 | Aluminum | A96061 | WW-T-700/6 | Tubing |

|

| AMS 4081 Round | 6061 | Aluminum | A96061 | MIL-T-7081 | Round |

|

| AMS 4081 Tubing | 6061 | Aluminum | A96061 | MIL-T-7081 | Tubing |

|

| AMS 4082 |

6061 | Aluminum | A96061 | WW-T-700/6 | Tubing |

|

| AMS 4127 Forging | 6061 | Aluminum | A96061 | QQ-A-367/H | Forging |

|

| AMS 4127 Ring | 6061 | Aluminum | A96061 | QQ-A-367/H | Ring |

|

| AMS 4162 |

6061 | Aluminum | A92219 | - | Extrusion |

|

| AMS 4248 |

6061 | Aluminum | A96061 | QQ-A-367 | Plate |

|

| AMS QQ A 200 16 Extrusion | 6061 | Aluminum | A96061 | QQ-A-200/16 | Extrusion |

|

| AMS QQ A 200 16 Shapes | 6061 | Aluminum | A96061 | QQ-A-200/16 | Shapes |

|

| AMS QQ A 200 8 Bar | 6061 | Aluminum | - | QQ-A-200/8 | Bar |

|

| AMS QQ A 200 8 Extrusion | 6061 | Aluminum | - | QQ-A-200/8 | Extrusion |

|

| AMS QQ A 200 8 Rod | 6061 | Aluminum | - | QQ-A-200/8 | Rod |

|

| AMS QQ A 200 8 Shapes | 6061 | Aluminum | - | QQ-A-200/8 | Shapes |

|

| AMS QQ A 200 8 Tubing | 6061 | Aluminum | - | QQ-A-200/8 | Tubing |

|

| AMS QQ A 200 8 Wire | 6061 | Aluminum | - | QQ-A-200/8 | Wire |

|

| AMS QQ A 225 8A Bar | 6061 | Aluminum | A96061 | QQ-A-255/8 | Bar |

|

| AMS QQ A 225 8A Rod | 6061 | Aluminum | A96061 | QQ-A-255/8 | Rod |

|

| AMS QQ A 225 8A Shapes | 6061 | Aluminum | A96061 | QQ-A-255/8 | Shapes |

|

| AMS QQ A 225 8A Wire | 6061 | Aluminum | A96061 | QQ-A-255/8 | Wire |

|

| AMS QQ A 250 11 Plate | 6061 | Aluminum | A96061 | QQ-A-250/11 | Plate |

|

| AMS QQ A 250 11 Sheet | 6061 | Aluminum | A96061 | QQ-A-250/11 | Sheet |

|

| AMS T 7081 |

6061 | Aluminum | - | MIL-T-7081D | Tubing |

|

| AMS WW T 700 6 |

6061 | Aluminum | - | WW-T-700/6F | Tubing |

|

Tech Steel & Materials

Tech Steel & Materials